Industry: Paint and lacquer industry

End product: Decorative Emulsion Paint

Application: Dispersing pigments and fillers in water

Process plant for architectural coatings

Our customers include the world's leading dispersed paint manufacturers Many of whom have now abandoned traditional production processes and switched to Wahal Engineer's liquid powder mixer technology.

We are committed to serving all of our customers, individually, with the full potential of the operation. Together we explore the whole chain of processes and identify each concept in order to find the best solution. Whether we connect each machine to existing process vessels or set up a complete, turnkey system: High efficiency is our gold standard.

Advantages compared to the previous process:

Wahal Engineer liquid powder mixer allows our customers to better position themselves in the future. The simplification of process steps means that there is a greater potential for productivity adjustment. Our plants not only reduce production times significantly but also provide greater savings compared to conventional production methods in terms of raw materials and energy consumption.

Wahal liquid powder mixer covers 5 steps of the process -

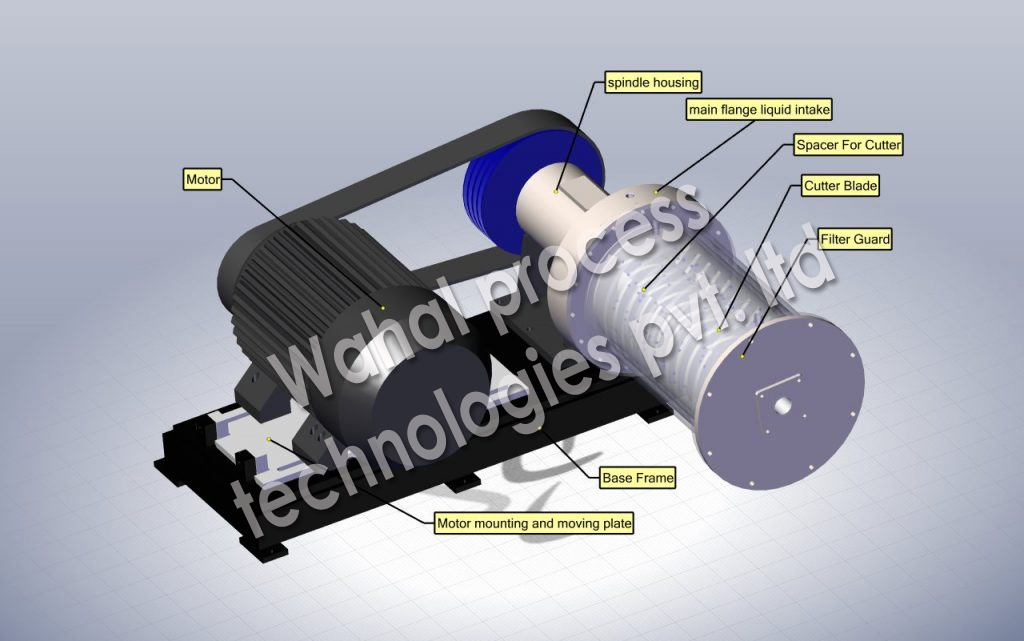

Following Wahal machines will help you understand the industry better!

Wahal High-Speed Disperser

Active industry: A double-shelf disperser is active in the chemical industry, such as printing ink, paint, adhesives and paints, etc.

Function: This machine is suitable for product dispersing, mixing, blending and other production processes.

Principle of operation: The dispenser can not only distribute building materials with a low need for refinement but also combine them into direct storage products. Disperser's sawtooth disperser impeller moves very fast to attach to the vessel while rotating at high speed. Material particles become smaller particles during a strong impact with shear force. The impeller blade mixing is made in accordance with the size of the material tank to fully dissolve the contents of the tank and to meet the requirements of the production process.

Tips: You can increase the processing rate, resource form, size requirements or the area of the items you need to process. Sower Marketing Engineers will provide you with solutions to your satisfaction.

Features

1. Adequate processing of building materials

2. Hydraulic lift ensures stability and reliability

3. Great potential for processing power

4. Form mixing of two shafts

Wahal High-Speed Dissolver

If you thought it would never happen, think again. The Wahal Engineer Power System integrator for Disintegrator will disperse, melt or disperse the most solid solids - up to 40 ′ ′ across - in a single operation, and sometimes you would not believe it. The Disintegrator includes a powerful and unique Wahal Engineer mixer available under a custom-built ship. The mixer pulls heavily down from the surface of the liquid, pulling down even solid objects that overflow, no matter what size. These solids are literally separated and dispersed throughout the mixture, and with the adjustment of the Wahal Engineer In-Line mixer installed in the system, it is completely melted or suspended. For small solids, Wahal Engineer offers a Duplex Disintegrator / Dissolver, specially designed to disperse and dissolve solid rubber and polymers for the oil and adhesive oil industry.

How It Works

The Disintegrator is an independent high-power unit that incorporates a Wahal Engineer high shear rotor/stator dispersing function headset into a custom-built dedicated vessel integrated with the Wahal Engineer high shear In-Line mixer.

Disintegrator / Solvents

The unit is charged with liquid and started. A large solid is inserted into the vessel and then pulled down to the working tip which will quickly cut the lumps and cut at the edges and corners. These will be pulled inside the work head, driven by centrifugal force on the periphery and also cut off the rotor tips against the edges of the stator perforations as they are fired by heat from the head.

The rapid disintegration of large solids continues until all particles are small enough to be pulled to the working surface to continue dispersing. The materials are horizontally removed from the work surface and forced to the top of the ship's walls. This cycle continues until all solid matter is reduced to granular size.

Once the solids have been reduced to a granular size the self-pumping In-Line mixer is started. The product is pulled from the bottom of the vessel, processed by the In-Line function of the shear high rotor/stator and then transferred back to the top of the vessel to ensure complete resolution or suspension.

General Applications

A quick solution for rubber and polymer blocks on lubricants, solvents and asphalt for the production of VM lubricants, adhesives and polymer modified asphalt open road.

Getting a waste candy.

Wet deterioration of waste rubber.

The rapid spread of large volumes of powder or substances that are hard to wet and have a tendency to “rescue.”

Dispersion of filter cakes.

Feel free to discuss our products with our officials and visit us on the Wahal website