The Pharma Industry is an essential component of the healthcare system throughout the world. It is mainly based upon scientific research and the development of injectables that prevent and treat various diseases and disorders. From discovering the active ingredient to manufacturing the finished product, the production of a drug is time-consuming, complex, and expensive

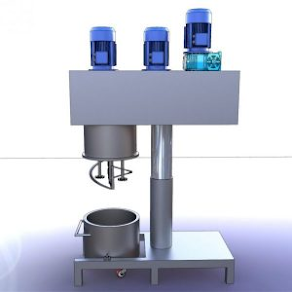

- Planetary Mixer/Double Planetary Mixers: Wahal Engineers developed and extended the horizon of Planetary Mixer by incorporating High Viscosity Blades in design, raising the maximum viscosity range to around 6 million cP. Thus, offering better cleanability, a smaller footprint, and lower capital cost. Wahals’ PowerMix Planetary Disperser (PDM) reaches high enough viscosities where kneading can be effective and are designed for high shear intensity and faster solids dispersion. This being our latest addition to the planetary mixing line of industrial mixers known as the Planetary Dual Disperser (PDDM). PDDM delivers uninterrupted processing power for advanced batteries, adhesives, composites, pharmaceuticals, coatings, and chemicals.